INNOVATION IS IN OUR NATURE

For us, product development and innovation go hand in hand. We relentlessly explore new technology and seek opportunities to expand our portfolio while uncovering the vast potential of krill.

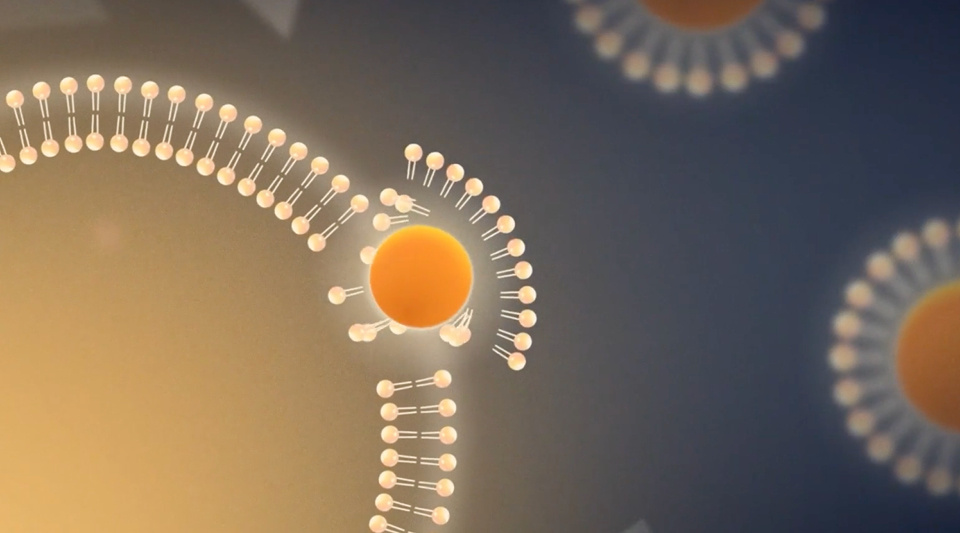

PL+ Technology™

PL+ Technology™ is a phospholipid-based delivery platform developed to boost the absorption of dietary supplements. Bioavailability and absorption of some supplements such as DHA and EPA, Curcumin, CoQ10 and CBD are erratic due to their poor solubility in gastrointestinal tract. Our proprietary PL+ Technology™ enables dual solubility in water and in fats, and enhances bioavailability of several important nutrients.

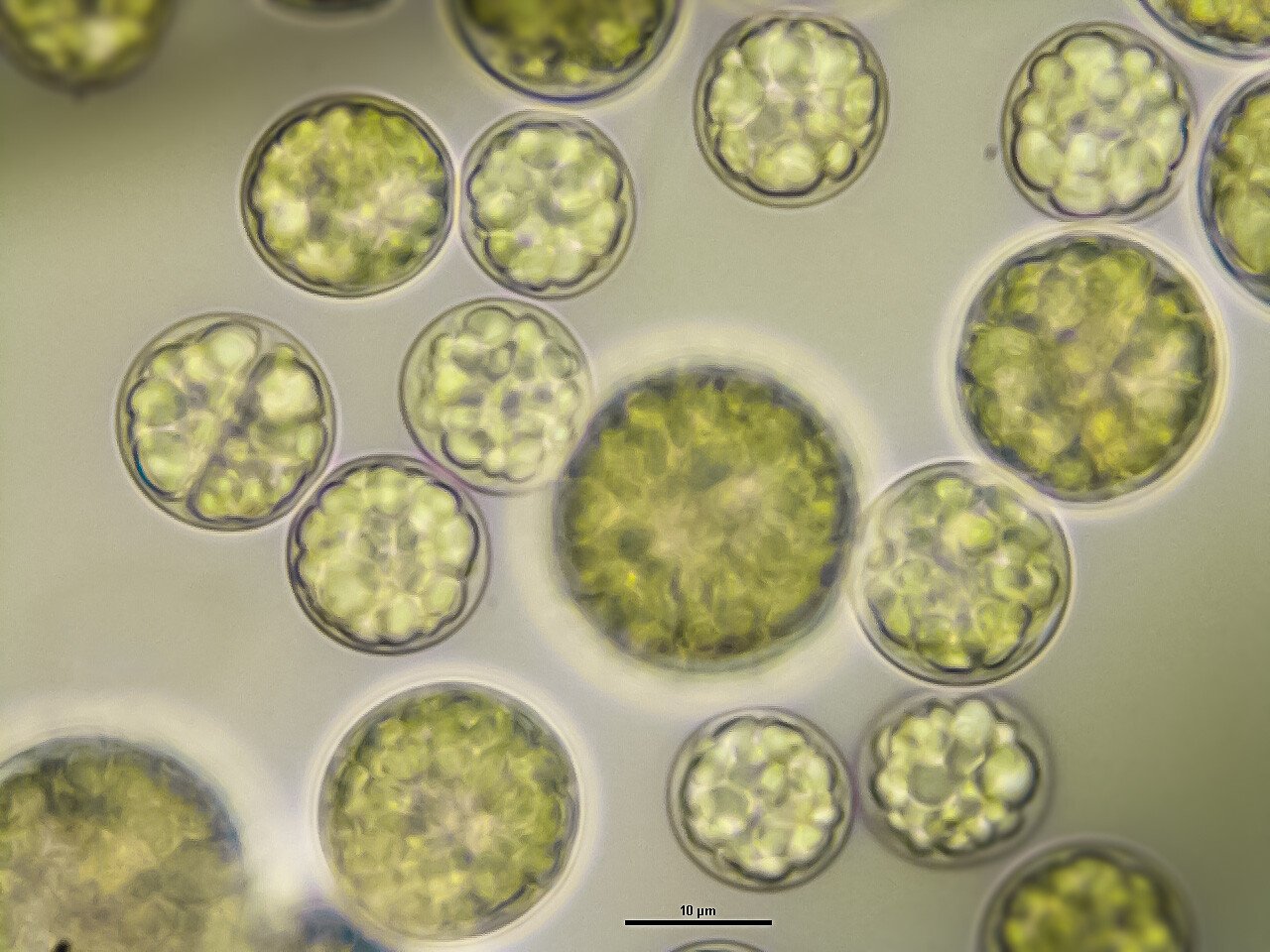

Revervia®

Revervia® is a new vegan DHA omega-3 oil from algae, delivering one of the highest concentrations of DHA on the market today. The Revervia brand builds on Aker BioMarine’s strong position as a trusted expert in marine source omega-3 for the nutraceutical industry.

Superba Krill®

Next generation krill oil supplements are based on continued optimization in manufacturing and purification technology to provide high concentration of purified, phospholipid rich krill oil free of contaminants and heavy metals.

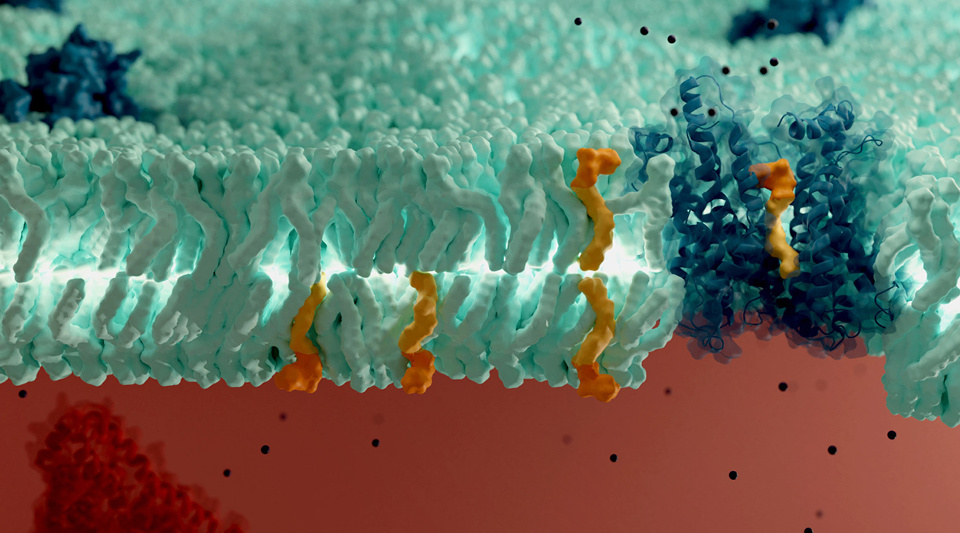

Lysoveta®

Essential fatty acids like EPA and DHA have proven to be important for healthy functioning of organs such as the brain, reproductive organs, eyes and skin. Scientific breakthroughs have shown that EPA and DHA are transported to these organs in the specific forms of LPC by a transporter named Mfsd2a. LYSOVETA® is a lyso-phosphatidylcholine (LPC) rich lipid extract from krill, unlocking new opportunities to explore targeted delivery of EPA and DHA to vital organs.

Understory®

Understory® is Aker BioMarine’s new protein brand. Antarctic krill protein provides a complete, well balanced amino-acid profile and has naturally occurring minerals, important to support and maintain vital functions in the body. Through our innovative and patented process, we have enhanced nutrition from this natural resource and enabled unique product development opportunities.

CaPre®

A new therapeutic candidate developed to manage and treat cardiometabolic diseases, particularly severe HTG, with limited side effects. CaPre® is a unique formulation that cannot be synthesized or easily copied, based on phospholipids forms of EPA and DHA derived from krill.

KRBNX®

KRBNX® offers next generation biostimulants and fertilizers. Based on a range of krill derived products from Aker BioMarine, KRBNX® serves as an outlet for high-quality byproduct from core operation. Scientific reviews of key ingredients points to a great potential in agriculture as organic fertilizers, biostimulants and soil conditioning.

GRANTED PATENTS AND PENDING APPLICATIONS

Below is a list of our patent rights in the most important markets for our products. A full overview of all our patents and patent applications is available through your chosen patent search service.

| Product Category | Country | Patent Number | Application Number | Issue Date | Title |

| Krill oil | AT | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | AU | 2008231570 | 2008231570 | 25-Jan-2012 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | AU | 2012101335 | 2012101335 | 20-Sep-2012 | PROCESSES AND PRODUCTS THEREOF |

| Krill oil | BE | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | CA | 2682068 | 2682068 | 28-Nov-2017 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | CH | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | DE | 60 2008 024 566.7 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | DK | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | EP | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | ES | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | FI | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | FR | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | GB | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | IE | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | IT | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | LU | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | NL | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | NO | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | PL | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | SE | 2144618 | 08718910.6 | 15-May-2013 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | US | 9,644,170 | 15/180,439 | 09-May-2017 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | US | 9,889,163 | 15/589,591 | 13-Feb-2018 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | US | 10,010,567 | 15/589,605 | 03-Jul-2018 | BIOEFFECTIVE KRILL OIL COMPOSITIONS |

| Krill oil | US | 8,697,138 | 12/790,575 | 15-Apr-2014 | METHODS OF USING KRILL OIL TO TREAT RISK FACTORS FOR CARDIOVASCULAR, METABOLIC, AND INFLAMMATORY DISORDERS |

| Krill oil | US | 9,730,966 | 14/968,183 | 15-Aug-2017 | METHOD OF REDUCING APPETITE IN A HUMAN SUBJECT COMPRISING ADMINISTERING KRILL OIL COMPOSITION |

| Krill oil | AU | 2016201168 | 14/035,167 | 12-Jul-2018 | LIPID EXTRACTION PROCESSES |

| Krill oil | EP | 3008156 | 2016201168 | 07-Jun-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | ES | 3008156 | 201480041687.1 | 07-Jun-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | GB | 3008156 | 14792582.0 | 07-Jun-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | NO | 3008156 | 14792582.0 | 07-Jun-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | PL | 3008156 | 14792582.0 | 07-Jun-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | UP | 3008156 | 14792582.0 | 07-Jun-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | US | 10,704,011 | 14792582.0 | 07-Jul-2020 | LIPID EXTRACTION PROCESSES |

| Krill oil | US | 11,578,289 | 14792582.0 | 14-Feb-2023 | LIPID EXTRACTION PROCESSES |

| Krill oil | AU | 2015205525 | 14/303,835 | 29-Mar-2018 | PHOSPHOLIPID COMPOSITIONS AND THEIR PREPARATION |

| Krill oil | CA | 2936327 | 16/741,062 | 15-Dec-2020 | PHOSPHOLIPID COMPOSITIONS AND THEIR PREPARATION |

| Krill oil | DE | 602015067174.0 | 2016-3119 | 24-Mar-2021 | PHOSPHOLIPID COMPOSITIONS AND THEIR PREPARATION |

| Krill oil | EP | 3094337 | 15753445.4 | 24-Mar-2021 | PHOSPHOLIPID COMPOSITIONS AND THEIR PREPARATION |

| Krill oil | GB | 3094337 | 15753445.4 | 24-Mar-2021 | PHOSPHOLIPID COMPOSITIONS AND THEIR PREPARATION |

| Krill oil | US | 9,867,856 | 15753445.4 | 16-Jan-2018 | PHOSPHOLIPID COMPOSITIONS AND THEIR PREPARATION |

| Krill oil | US | 11,020,438 | 15753445.4 | 01-Jun-2021 | |

| Krill oil | US | 10,960,016 | 14/728,101 | 30-Mar-2021 | CAPSULES CONTAINING HIGH DOSES OF KRILL PHOSPHOLIPIDS |

| Krill oil | US | 10,806,742 | 14/965,433 | 20-Oct-2020 | LIQUID PHOSPHOLIPID-CONTAINING COMPOSITIONS FOR THE PREPARATION OF PHARMACEUTICALS |

| Krill oil | AU | 2016217566 | 2016217566 | 30-May-2019 | LIPID COMPOSITIONS |

| Krill oil | AU | 2019203314 | 2019203314 | 08-Apr-2021 | LIPID COMPOSITIONS |

| Krill oil | BR | BR1120170173107 | BR1120170173107 | 26-Jul-2022 | LIPID COMPOSITIONS |

| Krill oil | ID | IDP000067491 | P00201706018 | 18-Feb-2020 | LIPID COMPOSITIONS |

| Krill oil | KR | 10-2079747 | 10-2017-7025430 | 14-Feb-2020 | LIPID COMPOSITIONS |

| Krill oil | KR | 10-2310765 | 10-2020-7004436 | 01-Oct-2021 | LIPID COMPOSITIONS |

| Krill oil | KR | 10-2515207 | 10-2021-7031460 | 24-Mar-2023 | LIPID COMPOSITIONS |

| Krill oil | NZ | 735362 | 735362 | 30-Apr-2019 | LIPID COMPOSITIONS |

| Krill oil | NZ | 747847 | 747847 | 03-Oct-2023 | LIPID COMPOSITIONS |

| Krill oil | RU | 2718983 | 2017129161 | 15-Apr-2020 | LIPID COMPOSITIONS |

| Krill oil | US | 10,864,223 | 15/040,347 | 15-Dec-2020 | LIPID COMPOSITIONS |

| Krill oil | US | 11,819,509 | 17/116,418 | 21-Nov-2023 | LIPID COMPOSITIONS |

| Krill oil | CH | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | DE | 602016076191.2 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | EP | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | ES | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | FR | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | GB | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | IT | 502023000006120 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | NO | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | PL | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | PT | 3256003 | 16709814.4 | 09-Nov-2022 | LIPID EXTRACTION PROCESSES |

| Krill oil | US | 10,456,412 | 15/040,330 | 29-Oct-2019 | LIPID EXTRACTION PROCESSES |

| Krill oil | IL | 248521 | 2021-575425 | 31-Jul-2020 | KRILL OIL PREPARATIONS AND THEIR USES |

| Krill oil | US | 10,898,525 | 10-2022-7001848 | 26-Jan-2021 | KRILL OIL PREPARATIONS AND THEIR USES |

| Krill oil | US | 9,650,590 | 18/226,395 | 16-May-2017 | SEPARATION OF POLAR LIPIDS FROM KRILL OIL EXTRACT |

| Krill oil | US | 9,650,333 | 15/382,085 | 16-May-2017 | PROCESS FOR SEPARATING ASTAXANTHAN |

| Krill oil | AU | 2021254620 | BIOEFFECTIVE KRILL OIL COMPOSITIONS | ||

| Krill oil | US | 18/511,243 | LIPID COMPOSITIONS | ||

| Krill oil | GB | 3143586 | USES FOR PHOSPHOLIPID COMPOSITIONS | ||

| Krill oil | WO | 202080054624.5 | USES FOR PHOSPHOLIPID COMPOSITIONS | ||

| Krill oil | CN | 17/903,208 | LIPID EXTRACTION PROCESSES | ||

| Krill oil | CN | 202111524749.2 | LIPID COMPOSITIONS | ||

| Krill oil | EP | 16716056.3 | LIPID COMPOSITIONS | ||

| Krill oil | US | 15/915,439 | BIOEFFECTIVE KRILL OIL COMPOSITIONS | ||

| Lysoveta | EA | 043427 | IPR2017-00746 | 24-May-2023 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS |

| Lysoveta | ID | P00202005137 | 13/545,830 | 17-Apr-2023 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS |

| Lysoveta | US | 11,065,267 | P00202005137 | 20-Jul-2021 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS |

| Lysoveta | US | 12,076,333 | 17/370,703 | 03-Sep-2024 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS |

| Lysoveta | US | 10,117,882 | 21721272.9 | 06-Nov-2018 | ANTI-INFLAMMATORY PROPERTIES OF MARINE LIPID COMPOSITIONS |

| Lysoveta | US | 10,525,068 | 2022-559535 | 07-Jan-2020 | ANTI-INFLAMMATORY PROPERTIES OF MARINE LIPID COMPOSITIONS |

| Lysoveta | US | 11,400,105 | 10-2022-7037654 | 02-Aug-2022 | ANTI-INFLAMMATORY PROPERTIES OF MARINE LIPID COMPOSITIONS |

| Lysoveta | US | 10,555,957 | PCT/IB2023/056584 | 11-Feb-2020 | METHODS AND COMPOSITIONS FOR ENRICHING DHA LEVELS IN THE BRAIN |

| Lysoveta | US | 11,744,864 | 16/734,850 | 05-Sep-2023 | METHOD OF TREATING EYE DISEASES WITH KRILL OIL |

| Lysoveta | KR | 201880086246.1 | 04-Sep-2024 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | |

| Lysoveta | AU | 2018-433 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | BR | 15/239,259 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | HK | 13/189,714 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | IL | 2018389595 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | MX | 202091399 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | NZ | 18855122.0 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | SG | 62021029120.4 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | AU | 19714777.0 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | BR | 19714777.0 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | EA | 19714777.0 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | IL | 19714777.0 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | MX | 15/307,764 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | NZ | 2020298105 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | AU | 20221173 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| Lysoveta | CA | IPR2017-00745 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | CN | IPR2017-00747 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | EP | 15/260,217 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | IN | BR1120200127051 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | JP | 3086416 | LYSOPHOSPHATIDYLCHOLINE COMPOSITIONS | ||

| Lysoveta | CA | 19714777.0 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | CN | 766794 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | EP | 19714777.0 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | JP | 17/745,104 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | KR | 248521 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | US | BR1120210254773 | PARENTERAL LYSOPHOSPHATIDYLCHOLINE FORMULATIONS SUCH AS LPC-DHA, LPC-EPA AND THEIR USE IN THERAPY | ||

| Lysoveta | US | 17/218,760 | ANTI-INFLAMMATORY PROPERTIES OF MARINE LIPID COMPOSITIONS | ||

| Lysoveta | CA | 18/381,439 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| Lysoveta | CN | PCT/IB2023/060534 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| Lysoveta | EP | 15/976,481 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| Lysoveta | JP | 12/849,950 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| Lysoveta | KR | 16/180,564 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| Lysoveta | US | 17/874,677 | KRILL OIL COMPOSITION ENRICHED IN LPC-DHA AND LPC-EPA | ||

| PL+ | DE | 602013069676.4 | 95/001,819 | 03-Jun-2020 | OMEGA-3 COMPOSITIONS |

| PL+ | EP | 2897595 | 95/001,774 | 03-Jun-2020 | OMEGA-3 COMPOSITIONS |

| PL+ | GB | 2897595 | 13836209.0 | 03-Jun-2020 | OMEGA-3 COMPOSITIONS |

| PL+ | US | 10,105,376 | 20177787.7 | 23-Oct-2018 | OMEGA-3 COMPOSITIONS |

| PL+ | US | 11,147,841 | 16/582,618 | 19-Oct-2021 | ENHANCED OMEGA-3 FORMULATIONS |

| PL+ | US | 12,023,359 | 20734501.8 | 02-Jul-2024 | PHOSPHOLIPID COMPOSITIONS FOR DELIVERY OF BIOACTIVE COMPOUNDS |

| PL+ | NO | 202193176 | PHOSPHOLIPID COMPOSITIONS FOR DELIVERY OF BIOACTIVE COMPOUNDS | ||

| PL+ | WO | 289096 | PHOSPHOLIPID COMPOSITIONS FOR DELIVERY OF THERAPEUTIC COMPOUNDS | ||

| PL+ | EP | 13836209.0 | OMEGA-3 COMPOSITIONS | ||

| PL+ | US | 13836209.0 | OMEGA-3 COMPOSITIONS | ||

| Understory | AT | 3749339 | 202017030922 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | BE | 3749339 | 10-2020-7021085 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | CH | 3749339 | 11202005905T | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | DE | 3749339 | 16/229,031 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | DK | 3749339 | 17/370,703 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | EP | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | ES | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | FI | 3749339 | BR1120200153699 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | FR | 3749339 | 3089673 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | GB | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | HK | 40042861 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | IE | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | IS | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | IT | 3749339 | 22179865.5 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | JP | 7516717 | 19714777.0 | 08-Jul-2024 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | LU | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | NL | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | NO | 3749339 | 620210331521 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | PL | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | SE | 3749339 | 19714777.0 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | TR | 3749339 | 2020-541505 | 03-Aug-2022 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT |

| Understory | AU | 2020-554958 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT | ||

| Understory | BR | MX/a/2020/006529 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT | ||

| Understory | NZ | 19714777.0 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT | ||

| Understory | CA | 765594 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT | ||

| Understory | EP | 2019214524 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT | ||

| Understory | KR | 19714777.0 | MARINE PROTEIN HYDROLYSATE WITH LOW FLUORIDE AND TRIMETHYLAMIN CONTENT | ||

| Understory | US | 10-2020-7022227 | PROTEIN HYDROLYSATES | ||

| Krill oil | AR | 20100104020 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | ||

| Krill oil | BR | 1,12012E+12 | 1,12012E+12 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | CA | 2779162 | 2779162 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | CA | 2989078 | 2989078 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | CL | 57.287 | 57.287 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | CN | ZL201080059930.4 | ZL201080059930.4 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | CN | ZL 201410490601.5 | ZL 201410490601.5 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | IL | 219457 | 219457 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | IL | 262567 | 262567 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | JP | 5827625 | 5827625 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | MX | 331404 | 331404 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | MX | MX/a/2014/010299 | MX/a/2014/010299 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | MX | 371752 | 371752 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | NZ | 600167 | 600167 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | PA | 89014-01 | 89014-01 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | SA | 3448 | 3448 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | TW | I573591 | I573591 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | US | 8586567 | 8586567 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | US | 9475830 | 9475830 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | US | 10130644 | 10130644 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | SA | 2012/03367 | 2012/03367 | CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITIONS | |

| Krill oil | CA | 3099660 | APPARATUS FOR METERING AND DISPENSING VISCOUS SUBSTANCE | ||

| Krill oil | CN | 2,0198E+12 | APPARATUS FOR METERING AND DISPENSING VISCOUS SUBSTANCE | ||

| Krill oil | HK | 62021038860.4 | APPARATUS FOR METERING AND DISPENSING VISCOUS SUBSTANCE | ||

| Krill oil | US | 11326922 | 11326922 | APPARATUS FOR METERING AND DISPENSING VISCOUS SUBSTANCE | |

| Krill oil | AU | 2020220816 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | BR | 1,12021E+12 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | CA | 3129365 | 3129365 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | |

| Krill oil | CN | 2,0208E+12 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | HK | 62022054366.9 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | IS | 285426 | 285426 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | |

| Krill oil | JP | 2021-547326 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | KR | 10-2021-7028729 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | NZ | 779464 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS | ||

| Krill oil | US | 17/427685 | PROCESS OF PRODUCING CONCENTRATED THERAPEUTIC PHOSPHOLIPID COMPOSITION FROM KRILL EXTRACTS CONTAINING HIGH LEVEL OF FREE FATTY ACIDS |