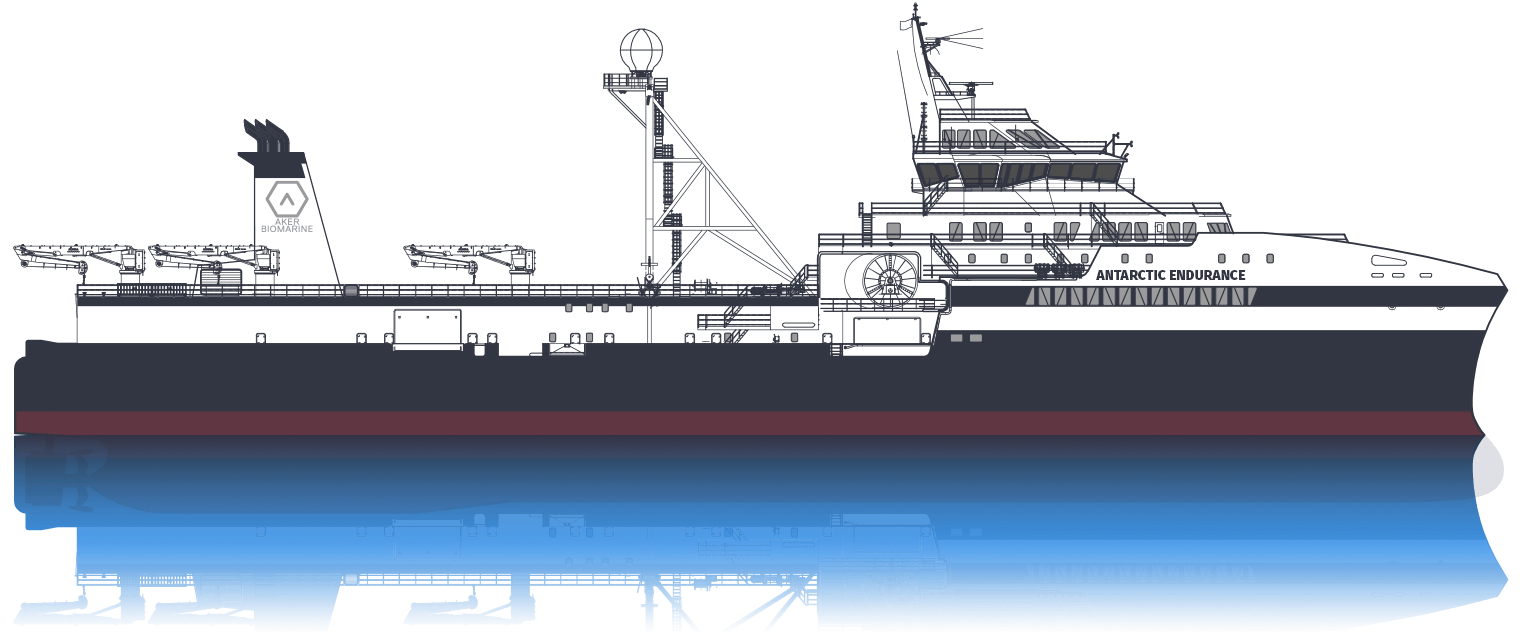

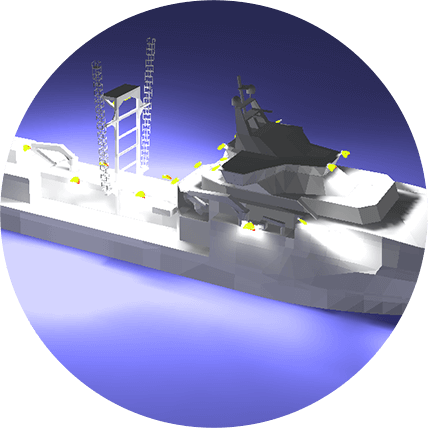

Antarctic Endurance

Aker BioMarine's Antarctic Endurance is the world's very first purpose-built krill harvesting vessel. The 130-meter vessel is constructed by Norwegian shipbuilders VARD.

Equipped with

Eco-Harvesting® technology

Leaving our annual by-catch at very low levels, among the lowest compared to other fisheries!

Setting a new bar for sustainable harvesting

Antarctic Endurance is custom built from scratch with innovative technologies that help make the vessel 30 percent more environmentally efficient, compared to other trawlers.

The vessel is equipped with the latest and most advanced eco-friendly technology, setting a new bar for sustainable harvesting.

In addition, the vessel has an onboard processing facility that processes the krill immediately after the krill is brought onboard, helping ensure premium product quality.

Length (L.O.A.): . . . . . . . . . . . . . . . . . . . . .

Breadth (MLD.): . . . . . . . . . . . . . . . . . . . . .

Crew size: . . . . . . . . . . . . . . . . . . . . .

129,6 meters

23 meters

70 persons

LED lightning

Deck lighting and searchlights utilize LED technology to reduce energy consumption, and will reduce the energy needed for lighting by a staggering 75 percent. The lights are constructed to handle difficult environments, like in Antarctica.

The LED lightning is delivered by Luminell.

Processing facility

The processing facility is designed to maximize efficiency, reusing energy throughout the whole process. For example, heat from one part of the process is used in another part of the process.

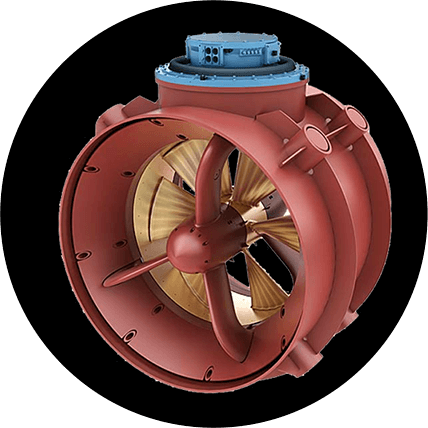

Tunnel thrusters

Antarctic Endurance has two tunnel thrusters designed to give the ship maximum side force when maneuvering. One of the thrusters is a swing-up thruster, which can be lowered below the ship's baseline for maximum bollard pull for optimal maneuvering.

Cinema and leisure area

The crew can enjoy movies in the 13 seat cinema. On the same floor there are two day rooms where the crew can socialize, or relax.

Mess room & galley

After work, the crew can enjoy a variety of healthy meals in the mess room. The ship has large freezers and coolers to keep ingredients fresh.

Bridge deck

The bridge is equipped with VARD’s SeaQ Bridge that includes a wide range of communication solutions, controlled and operated from the vessel's bridge. This provides an efficient, secure and ergonomic bridge environment.

Cabins for 70 persons

The new vessel is built to accommodate 70 people, and the crew is typically on board for several months at a time. That's why the ship is made crew friendly, with modern cabins and leisure areas. All lounges, mess rooms and gymnasium have large windows to ensure a bright environment and gives you the feeling of being in close contact with the beautiful and raw surroundings.

Gym and sauna

The crew's health and wellbeing are paramount. It is why the new vessel is equipped with recreational facilities such as a 37 square meter gym and a sauna with direct access to the outdoor jacuzzi, complete with heated water and of course a marvelous view.

Sky Lounge

On the top of the Antarctic Endurance the crew can relax and enjoy the view.

MOB Boat

For safety reasons the ship has a MOB (man overboard boat) rescue boat that can perform man-overboard retrieval and other time-critical operations.

Marine electronics

Antarctic Endurance is equipped with a number of innovative technologies, that help ensure optimal operations at sea. Such as, navigation systems from VARD, fish finding equipment from Kongsberg Simrad and safety equipment from Survitec.

Cargo hold

The cargo hold can accommodate 3 150 tonnes of processed krill. The product is offloaded while at sea to Aker BioMarine's own supply vessel, La Manche, which then transports the product to Montevideo, Uruguay. From here it is distributed to warehouses or directly to the end customer.

Research laboratory /

Quality control

The onboard laboratory is a vital part of our harvesting operations and our continued investment in research and development.

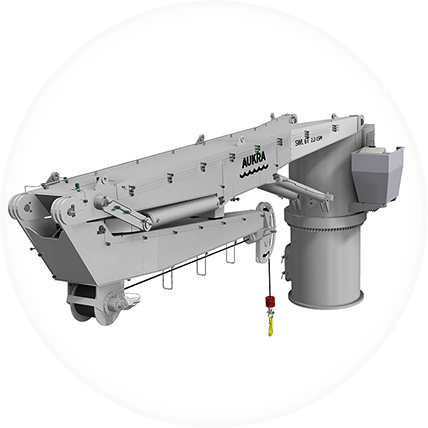

Cranes

The vessel has three cranes dedicated to offloading operations, with either heated or air-conditioned cabins. Inside the cargo deck there is an overhead traverse-crane that is remotely operated to assist crew with heavy lifting.

Eco-Harvesting

The third generation of the Eco-Harvesting technology features a triple-tank-sequence system that ensures a steady flow of Krill from the trawl at a constant vacuum. A hydraulic-driven wagon that runs up and down the shipside connects the Eco-Harvesting hose to a submerged inlet at 2,5 meters below the waterline. This helps reduce the risk of striking ice, avoid any possibility of air leakage and increase capacity.

Overskrift

Part1

Part2 (optional)

Overskrift

Part1

Part2 (optional)

Overskrift

Part1

Part2 (optional)

Cranes

The vessel has a total of four deck cranes. Two cranes are dedicated to offloading operations, with either heated or air-conditioned cabins and two cranes are dedicated to deck operations. Inside the cargo hold, there are two overhead traverse-cranes that are remotely operated to assist crew with cargo handling.

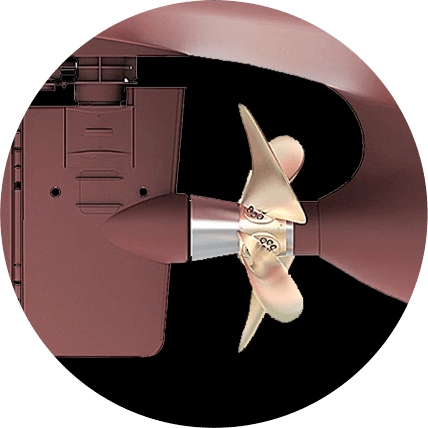

Propulsion and manoeuvring system

The Promas plus nozzle, the new propulsion and maneuvering system from Rolls Royce, combines a new type of nozzle with an optimized propeller, hubcap, rudder bulb and a special rudder profile, developed to provide very high steering forces yet minimize drag. The components are designed to work together in a ducted system, maximizing efficiency and helping to reduce fuel consumption.